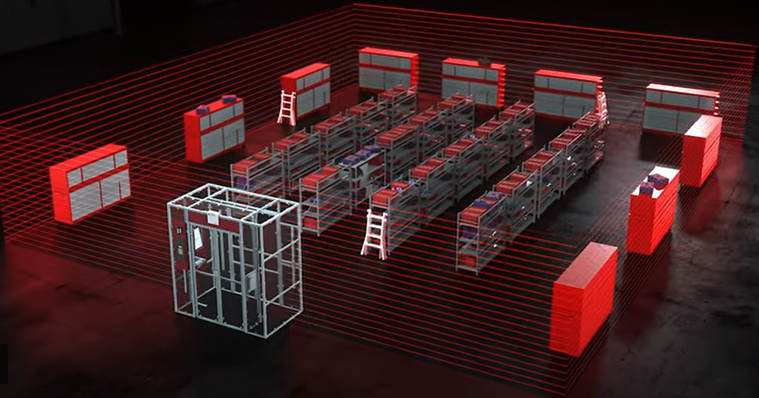

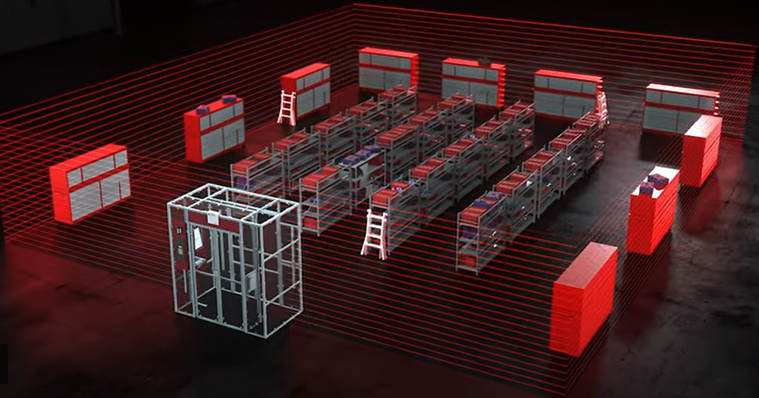

Inventory Management

A businesses inventory is critical to its ability to function smoothly and also within budget. Management of a businesses inventory can at times be challenging and potentially costly if not managed correctly. Smart inventory management systems can give multiple benefits:

- Live tracking of all items within the system - instantly know what is being used where and when using a live cloud based software solution, this allows for business to purchase just what they need as all stock is managed and tracked to an individual.

- Create minimum stock levels for the system to alarm - Data gathered within the system allows you to analyse usage and then make sure your stock levels are set to those minimum levels even when they potentially fluctuate through-out the year.

- Allows full data analysis - Allows businesses to asses data and make sure slow moving items do not tie up space or needless expense while fast moving items can be managed to prevent stock outs.

- Create minimum re-order quantities so the system automatic re-orders when you hit minimum stock quantities

Automate the Procurement Process

Businesses use ERP systems to simplify the procurement of items, however in a lot of instances these can still need an awful lot of manual input. Using smart industrial vending software this process can be automated based on the inventory levels and reorder levels you pre-set into the system.

- PO’s can be automatically generated from stock levels - When stock hits a specific level the system will automatically flag this to an administrator to show current stock levels and also the standard re-order quantities.

- Remove the need for manual purchase order generation - When stock hits a minimum level a PO can be automatically generated and sent straight through to the supplier in question. In doing so saving countless hours for the purchasing team.

- Remove the need for manual stock checks - When stock is fully controlled and locked down everything is tracked, which means the days of long hours going through stock counting it on a daily, weekly or quarterly basis are long gone.

What are some of the other benefits of industrial vending?