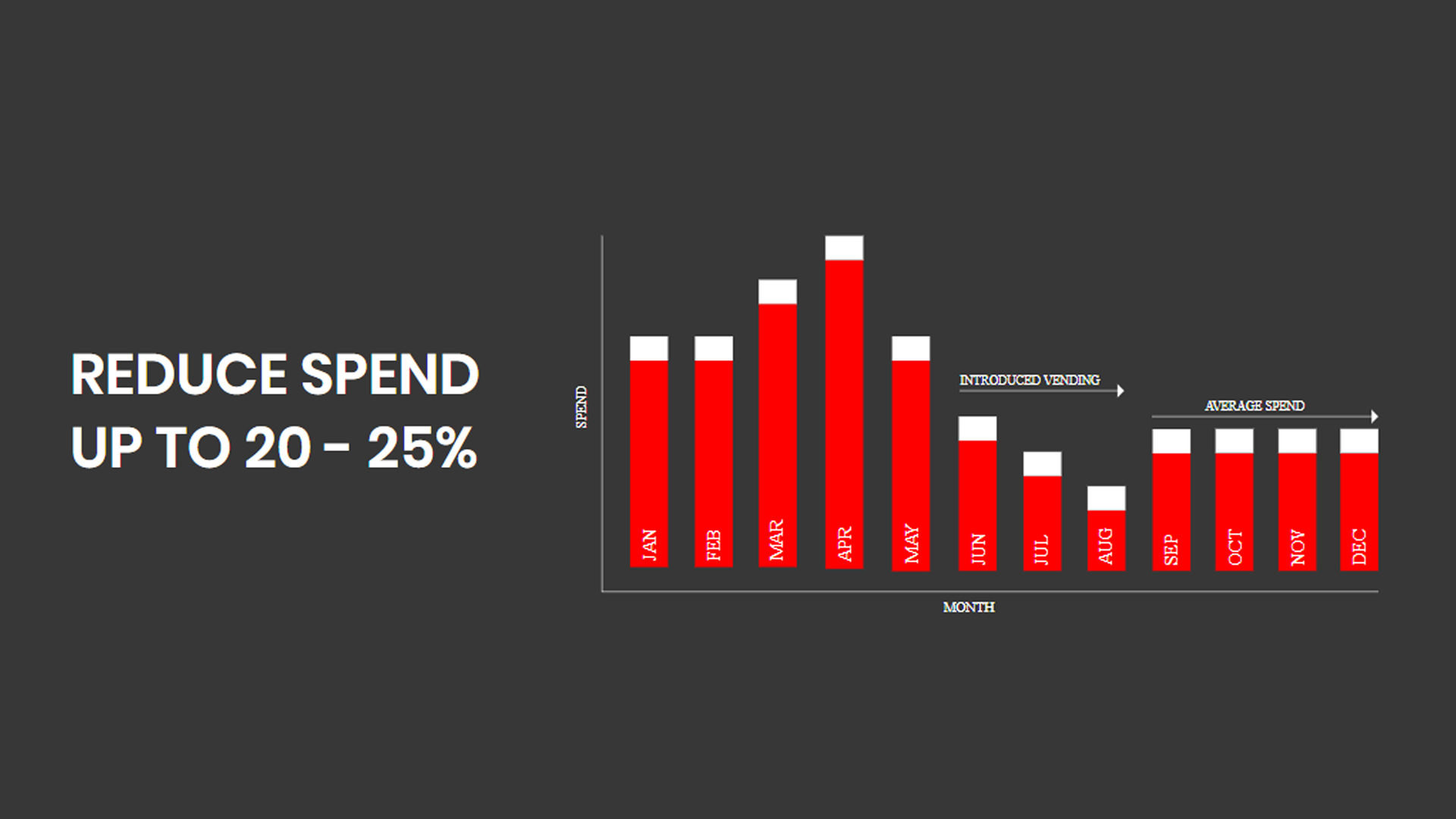

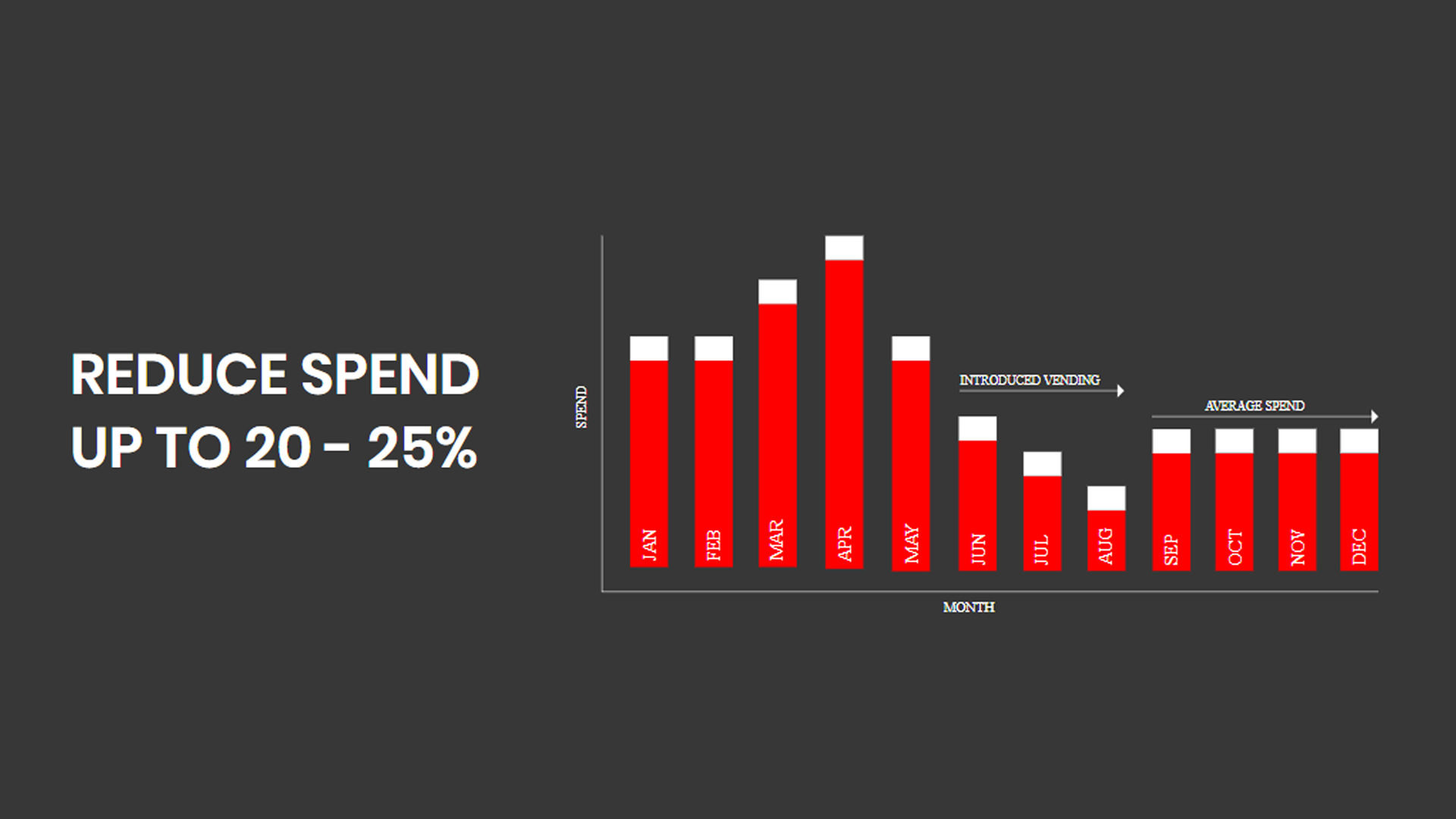

Reduce inventory expenses

Dependant on what specific items are being controlled, usage on average drops by 20%-40% but within some businesses we have seen this increase to as high as 70%.

By controlling stock items, it gives businesses the ability to vend only what is needed for the job whether that be tools, parts or even PPE. This eliminates the ability for users to take more than what they need with the potential that this stock is then not replaced into the system. It also gives ownership to the individual dispensing items out as those items are logged against that individual.

The system gives businesses the ability to then analyse all of the data as to where items are being used and how, which in turn can lead businesses to change practises in order to reduce costs.

Having full accountability for stock will also reduce the likelihood of extra items being taken, as the software offers full traceability and track ability as to what was taken, when and by whom.

Increase Productivity

Labour is normally one of the most expensive resources a business has at its disposal so increasing productivity is key. The examples of this range but a few key ones are:

- Downtime Reduction – Whenever downtime happens within manufacturing it will always affect operational productivity. By placing key parts and tools inside industrial vending solutions and moving them closer to points of use it gives engineering and operational teams the parts they need on hand to get operations back up and running efficiently and quickly.

- Moving Key Items Closer to Areas of Use – Travel time is a key factor that drives down productivity figures but having items on hand cuts down needless travel time.

- Cut Down Search Time – with intelligent management systems, inventory can either be vended immediately or items will be identified within current storage areas meaning staff will no longer spend time searching for these items.

- Reduce Preparation Time – most jobs need specific parts, tools & PPE. With intelligent systems & industrial vending machines, jobs can be set up with all items required. Rather than having staff members investigate what items they need and then go and collect the items a single job number is entered into the system and then all items are vended to the end user.

What are some of the other benefits of industrial vending?